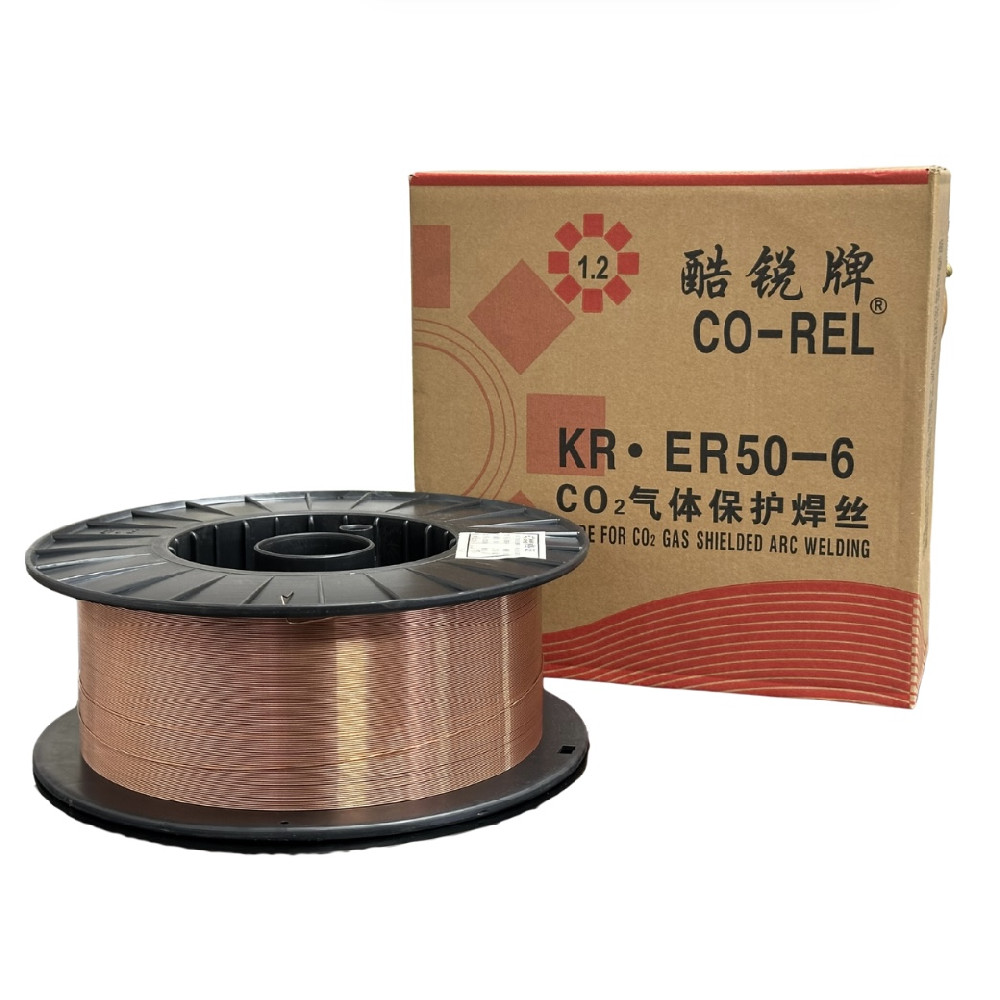

CO-REL® ER50-6 Gas Shielding Arc Welding Wire

Shielding Gas: CO₂Available Diameter (mm): 0.8 / 0.9 / 1.0 / 1.2 / 1.6Mechanical Performance of Deposit MetalTensile Strength MPa (N/mm²): ≥500Yield Strength (MPa): ≥420Elongation A (%): ≥22Impact Energy (J): -30℃≥27Application: Used for welding carbon steel and low alloy steel structures of

-

Standard:

KR·ER50-6

GB/T8110 - 2020ER50-6

AWS A5.18 - ER70S-6 - WhatsApp:+44 736311459

- Office: Jianfu Industrial Park, No.79 Wengexing Road, Liaobu Town, Dongguan City, Guangdong Province

- Email: info@coboltwelding.com

Product description

Application: Used for welding carbon steel and low alloy steel structures of corresponding strength grades, applicable to industries such as engineering machinery, shipbuilding, vehicle manufacturing, and petrochemicals.

Characteristics: This 500MPa grade carbon steel welding wire adopts CO₂ or Ar+CO₂ gas-shielded welding. It features low spatter, aesthetic weld formation, high deposition efficiency, low porosity susceptibility in weld metal, and excellent all-position welding processability.

Shielding Gas: CO₂

Available Diameter (mm): 0.8 / 0.9 / 1.0 / 1.2 / 1.6

Mechanical Performance of Deposit Metal

Tensile Strength MPa (N/mm²): ≥500

Yield Strength (MPa): ≥420

Elongation A (%): ≥22

Impact Energy (J): -30℃≥27

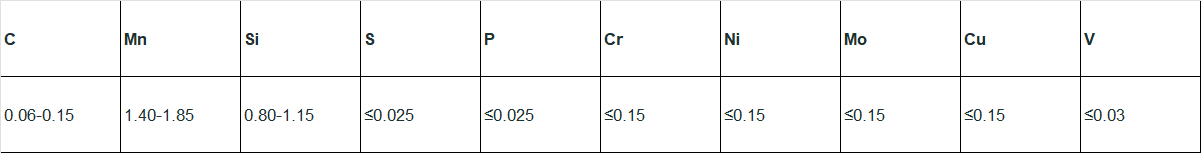

Chemical Composition (%):

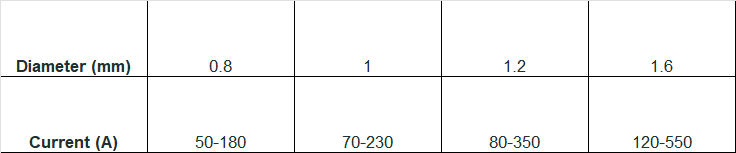

Welding Parameters

Current Polarity: DC+ (Direct Current Electrode Positive)

Precautions:

1. CO₂ shielding gas purity shall be ≥99.98%.

2. Gas flow rate shall be regulated to 20–25 L/min

(Calibrated flowmeter required).

3. Wire stick-out shall be maintained at 15–25 mm.