CO-REL® KR·308 (A102E) Stainless Steel Welding Rod

CO-REL® KR·308 (A102E)is atitania-calcium coated stainless steel electrode(AWS E308-16 equivalent) with excellent mechanical properties andhot cracking resistance. Applications include:Petrochemical reactorsFood processing pipelinesMedical equipmentOptimized forthin

-

Standard:

KR308 (A102E)

GB/T 983 - 2012

QB/KRJ018 -2012

AWS A5.4 E304-16 - WhatsApp:+44 736311459

- Office: Jianfu Industrial Park, No.79 Wengexing Road, Liaobu Town, Dongguan City, Guangdong Province

- Email: info@coboltwelding.com

Product description

CO-REL® KR·308 (A102E) is a titania-calcium coated stainless steel electrode (AWS E308-16 equivalent) with excellent mechanical properties and hot cracking resistance. Applications include:

Petrochemical reactors

Food processing pipelines

Medical equipment

Optimized for thin-sheet flat welding and low-automation manual SMAW. AC/DC compatible with exceptional AC arc stability, delivering a soft arc, low-spatter, and aesthetic bead appearance. Resists reddening during welding with all-position capability (1G/2G/3G/4G) and robust coating integrity.

Primary Use: Welding 0Cr18Ni9-type stainless structures requiring high crack resistance but moderate corrosion resistance (<300°C service).

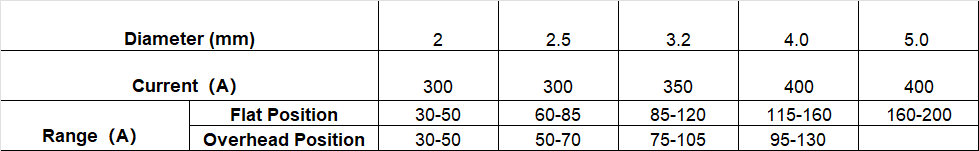

Available Diameter (mm): 2.5 / 3.2 / 4.0

Mechanical Performance of Deposit Metal

Tensile Strength MPa (N/mm²): ≥550

Elongation A (%): ≥25

Fillet of T Joint Weld Test: Passed

Baking Temperature Before Welding: 300-350℃ for 1 Hour

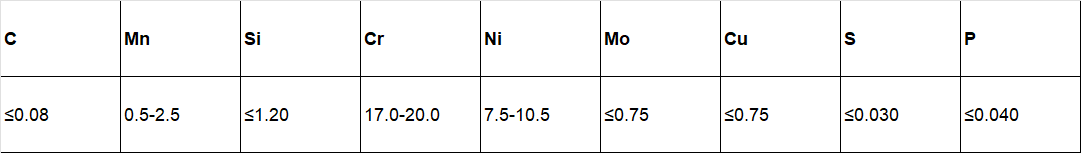

Chemical Composition (%)

Welding Parameters

Current Polarity: DC+ / AC

Precautions:

Electrodes shall be baked at 300–350°C for 1 hour before use (immediate consumption post-baking).

Minimize current input & maintain short arc; oscillation width ≤2.5×electrode diameter.

Base metal must be cleaned of oil, moisture, and contaminants pre-weld.