CO-REL® D707 Hardfacing Electrode

D707 Wear-Resistant Electrode (EDW-A-15)is alow-hydrogen sodium-coated carbon steel electrodewithtungsten carbide-infused coating. Designed for rebuilding rock-abrasion components in mining/construction machinery, including:Concrete mixer bladesBulldozer bladesDredger cutter

-

Standard:

KR·D707 (EDW-A-15)

GB/T 984 - 2001

QB/KRJ020 -2012 - WhatsApp:+44 736311459

- Office: Jianfu Industrial Park, No.79 Wengexing Road, Liaobu Town, Dongguan City, Guangdong Province

- Email: info@coboltwelding.com

Product description

D707 Wear-Resistant Electrode (EDW-A-15) is a low-hydrogen sodium-coated carbon steel electrode with tungsten carbide-infused coating. Designed for rebuilding rock-abrasion components in mining/construction machinery, including:

Concrete mixer blades

Bulldozer blades

Dredger cutter heads

Key Properties:

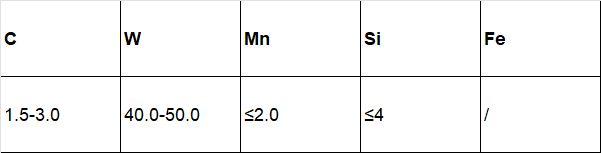

Tungsten content: 40–50% in deposit → HRC ≥65

AC/DC compatible (DC+ recommended)

Low-Current Advantage: Minimizes coating spallation, ideal for high-wear parts in:

Brick/tile plants (mixer shafts, crusher hammers)

Cement plants (grinding rolls, jaw plates)

Mining (dredge buckets, drill bits)

Steel mills (bells, hoppers)

Agriculture (cultivator blades, stalk shredders)

Applications: Rebuild components enduring severe rock abrasion, e.g.:

Pump impellers

High-speed sand mixers

Wood charcoal pushers

Sugar/paper mill wear parts

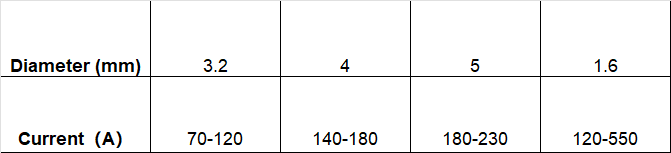

Available Diameter (mm): 3.2 / 4.0 / 5.0

Mechanical Performance of Deposit Metal

HRC≥65

Chemical Composition (%)

Welding Parameters

Current Polarity: DC+ / AC

Pre-Weld Protocols:

Baking: 300–350°C × 1h

Preheat:

Carbon steel: ≥300°C

Low-alloy steel: 400–500°C

Stainless steel: 600–650°C

Post-Weld Annealing: 700°C (mandatory for low-alloy/stainless steels)