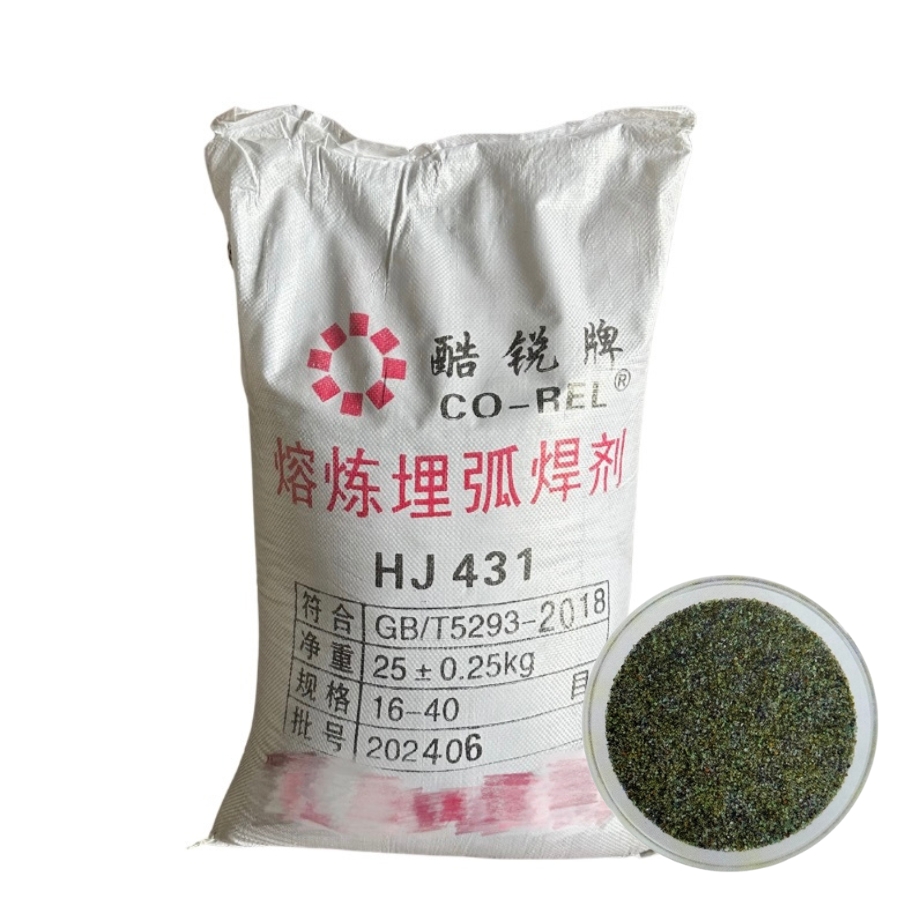

CO-REL® HJ431 (Fused) Submerged Arc Welding Flux

Application:CO-REL®HJ431 flux is designed for submerged arc welding with H08A, H08MnA, H10Mn2, and H10MnSi wires, suitable for carbon steels and low-alloy steels (e.g., 16Mn, 15MnV). Widely applied in shipbuilding, boilers, low-pressure vessels, and structural steel fabrication. Also co

-

Standard:

HJ431

NB/T47018.4-2022

GB/T5293-2018

GB/T36037-2018 - WhatsApp:+44 736311459

- Office: Jianfu Industrial Park, No.79 Wengexing Road, Liaobu Town, Dongguan City, Guangdong Province

- Email: info@coboltwelding.com

Product description

Application: CO-REL® HJ431 flux is designed for submerged arc welding with H08A, H08MnA, H10Mn2, and H10MnSi wires, suitable for carbon steels and low-alloy steels (e.g., 16Mn, 15MnV). Widely applied in shipbuilding, boilers, low-pressure vessels, and structural steel fabrication. Also compatible with electroslag welding and copper welding.

Characteristics: This low-manganese low-fluoride flux features light-to-dark green glassy particles with mesh sizes of 10-40, 12-40, or 16-40. Engineered specifically for structural steel fillet welds, it delivers:

- Superior slag detachment

- Exceptional gas pore resistance

- Smooth weld bead appearance

- Cost-effective stable welding performance.

Mechanical Performance of Deposit Metal

Tensile Strength MPa (N/mm²): 420-550

Yield Strength (MPa): ≥340

Elongation A (%): ≥22

Impact Energy (J): -20℃≥34

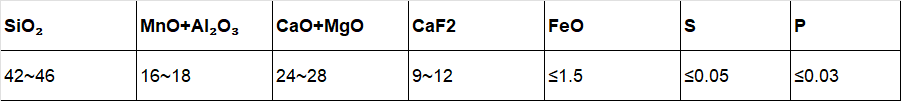

Chemical Composition (%)

Precautions:

1. Weld surfaces must be cleaned of oil, moisture, rust, and other contaminants prior to welding.

2. Storage conditions require strict moisture-proof measures.

3. Flux must be baked at 300–400°C for 2 hours before welding.