CO-REL® SJ101 (Sintered) Submerged Arc Welding Flux

CO-REL® SJ101 Sintered SAW Fluxis afluoride-basic sintered flux(basicity: 1.8) with gray-white spherical particles sized 2.0–0.28 mm (10–60 mesh). Compatible with AC/DC power sources, it operates optimally underDC+ polarity. Metallurgically neutral, itminimizes Si/Mn

-

Standard:

GB/T5293-2018

GB/T 12470 F48A2-H08MnA F48A4-H10Mn2

AWS A5.17 F7A2-EM12K F7A4-EH14 - WhatsApp:+44 736311459

- Office: Jianfu Industrial Park, No.79 Wengexing Road, Liaobu Town, Dongguan City, Guangdong Province

- Email: info@coboltwelding.com

Product description

CO-REL® SJ101 Sintered SAW Flux is a fluoride-basic sintered flux (basicity: 1.8) with gray-white spherical particles sized 2.0–0.28 mm (10–60 mesh). Compatible with AC/DC power sources, it operates optimally under DC+ polarity. Metallurgically neutral, it minimizes Si/Mn pickup in weld metal.

Process Advantages:

Superior arc stability

Effortless slag removal (no pitting/sticking)

Aesthetic bead profile

High low-temperature impact toughness

Specialized Performance:

90° fillet joints: Excellent slag peeling & smooth weld transition

High-current welding (≥800A) at 1.8 m/min: Gas pore resistance with ribbon-like slag detachment

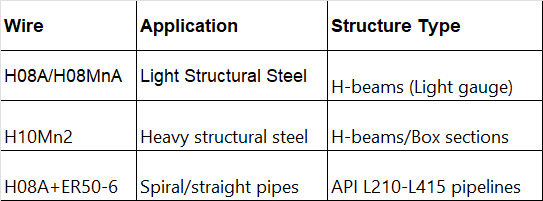

Wire Compatibility & Applications:

Critical Industries:

Ship hulls

Boilers & pressure vessels

Pipelines

Supports: Multi-pass, double-sided single-pass, tandem-wire, and narrow-gap SAW

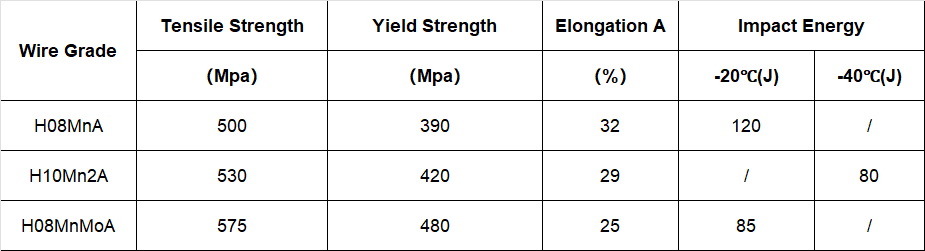

Mechanical Performance of Deposit Metal

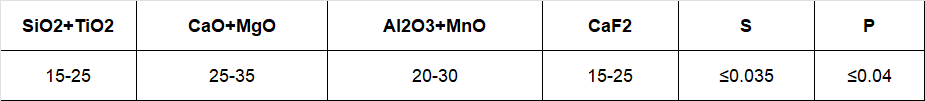

Chemical Composition (%)

Precautions:

1. Weld surfaces must be cleaned of oil, moisture, rust, and other contaminants prior to welding.

2. Storage conditions require strict moisture-proof measures.

3. Flux must be baked at 300–400°C for 2 hours before welding.

4. Excessive flux height impairs bead appearance.

5. Periodically replenish with fresh flux to prevent poor bead surface quality caused by reused flux.