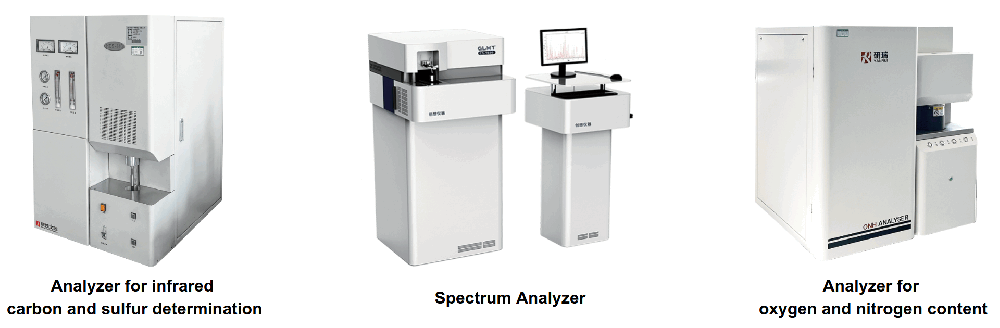

Inspection Capabilities

All upstream factories we collaborate with are equipped with industry-leading production and testing systems, strictly adhering to ISO9001 quality management standards. Our products are certified by CCC, CE, and seven major classification societies. Advanced equipment such as spectrometers and diffusion hydrogen testers are used to conduct triple testing for each batch of welding materials. Achieving a fully closed-loop quality control system throughout the entire process to guarantee zero defects in welding materials delivery.

Quality Assurance Protocol

Our upstream partners deploy spectrometric analysis to validate chemical composition against AWS/GB/EN standards, ensuring precise alloy content in every batch. Diffusion hydrogen testing rigorously measures H₂ levels to prevent cold cracking in critical applications. Each triple-test cycle encompasses:

-

Raw Material Inspection (ISO 10474:2013)

-

In-process Verification (Automated sampling at 30-min intervals)

-

Finished Product Certification (MTC with traceable heat number)

Certification-Driven Manufacturing

The seven classification societies' approval (including ABS, DNV, and CCS) mandates:

-

Welding Procedure Qualification

-

Batch Traceability with Digital Logs

-

Non-Destructive Testing (UT/RT for defect detection)

This multi-layered regime guarantees zero-defect delivery while maintaining full compliance with CE Machinery Directive 2006/42/EC and CCC China Compulsory Certification.

Leave your reply

Your email address will not be published. Required fields are marked *