Manufacturing Facilities

CO-REL® Welding Wire Production Base

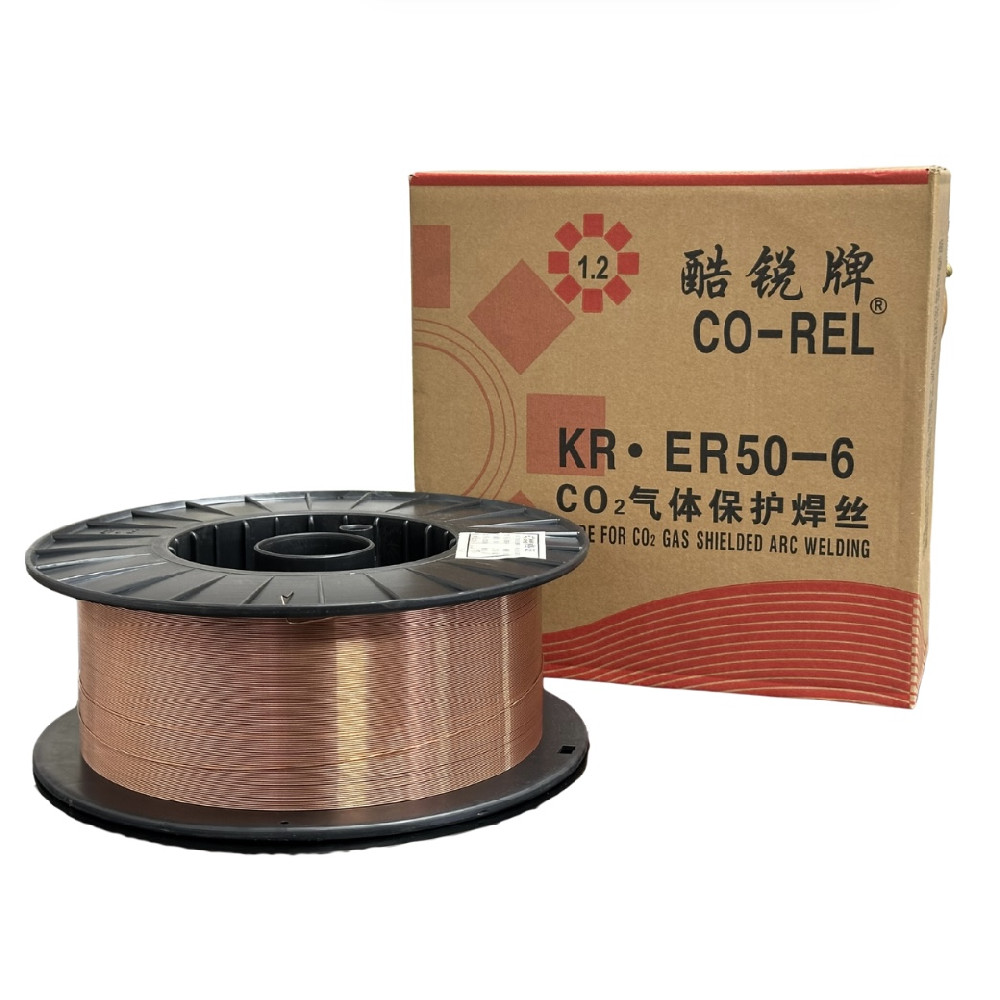

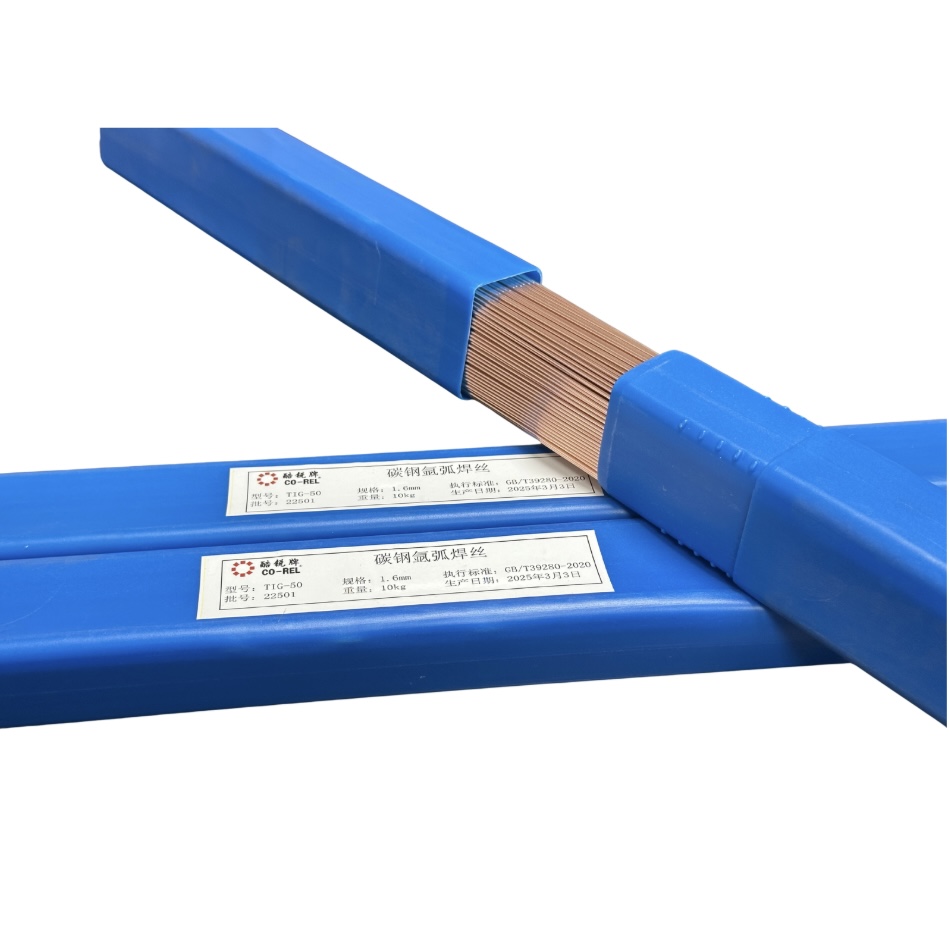

All CO-REL® brand's gas shielding welding wires, flux-cored welding wires, tungsten inert gas welding wires, and submerged arc welding wires are manufactured at our intelligent facility in Shandong, the annual production capacity of CO-REL®'s welding wire alone exceeds 12,000 metric tons. Equipped with China's pioneering fully automated integrated production line, the plant seamlessly executes eight critical processes: wire drawing, copper coating, drying, polishing, spooling, coil reversing, sorting, and packaging. Raw materials undergo precision single-pass forming from intake to finished products. This revolutionary system ensures zero-defect quality control while tripling production efficiency compared to conventional methods, setting new benchmarks for welding consumables manufacturing.

CO-REL® Submerged Arc Welding Flux Production Base

Located in Hunan Province, this facility covers over 20,000 square meters and possesses industry-leading R&D capabilities for raw material formulations. With an annual production quantity exceeding 50,000 metric tons, it provides stable supply to multiple leading domestic enterprises, including over 6,000 tons of CO-REL® submerged arc welding flux.

The production process encompasses:

1. Raw material batching

2. Smelting

3. Drying

4. Particle screening

5. Quality inspection

6. Packaging

7. Outbound logistics

Automation is implemented throughout the entire production process. Also, there is a central control room monitoring operations via an integrated control panel, recording real-time production data. Visualised process management enhances production efficiency while ensuring rigorous quality control.

Leave your reply

Your email address will not be published. Required fields are marked *