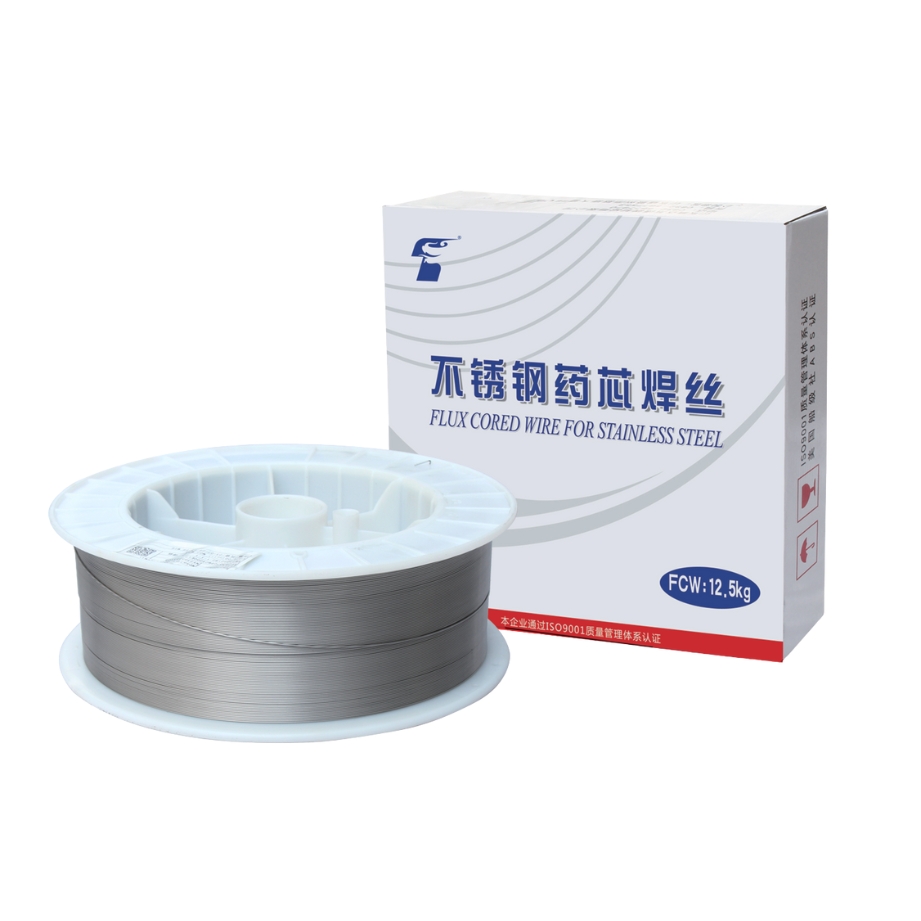

TENGDA Stainless Steel Flux Cored Welding Wire

When using carbon dioxide as shielding gas, thisflux-cored stainless steel welding wireenableshigh-efficiency continuous weldingwith:Deposition rate 2-3× higherthan manual electrodesDeposition efficiency ≥85%Exceptional operabilityunderCO₂ shielding gas&n

-

Standard:

GB/T 19001/24001/45001

IATF16949

AEO

GJB9001C

Classification Society Certification - WhatsApp:+44 736311459

- Office: Jianfu Industrial Park, No.79 Wengexing Road, Liaobu Town, Dongguan City, Guangdong Province

- Email: info@coboltwelding.com

Product description

When using carbon dioxide as shielding gas, this flux-cored stainless steel welding wire enables high-efficiency continuous welding with:

Deposition rate 2-3× higher than manual electrodes

Deposition efficiency ≥85%

Exceptional operability under CO₂ shielding gas (purity ≥99.98%)

Process Advantages:

Gas-slag dual shielding (from flux-filled metal sheath) → Stable arc & minimal spatter

Easy slag removal & aesthetic bead profile

High NDT pass rate

Simplified parameter setup for semi-automatic/robotic welding

With mixed gas shielding (75-80% Ar + CO₂), this flux-cored wire enables high-efficiency continuous welding:

Deposition rate 2-3× higher than SMAW electrodes

Deposition efficiency ≥85%

Gas-slag dual shielding (flux-filled core) → Stable arc, minimal spatter, easy slag removal, aesthetic bead

High NDT pass rate

Simplified parameterization for semi-automatic/robotic welding

Global Applications:

Rail transit • Auto mufflers • Pressure vessels (ASME Sec. VIII)

Chemical equipment • Machinery • Shipbuilding

Quality Assurance:

Multi-stage QC protocol from raw materials → production → delivery ensures premium performance.

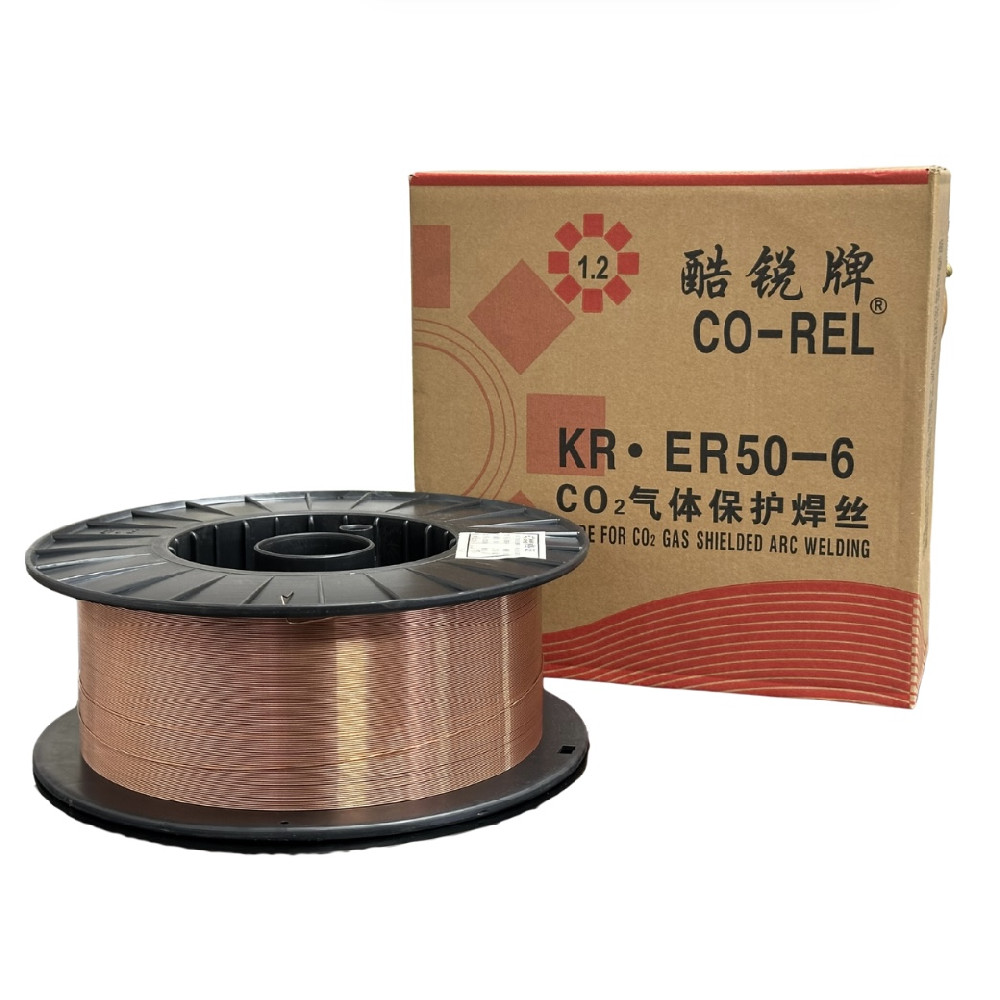

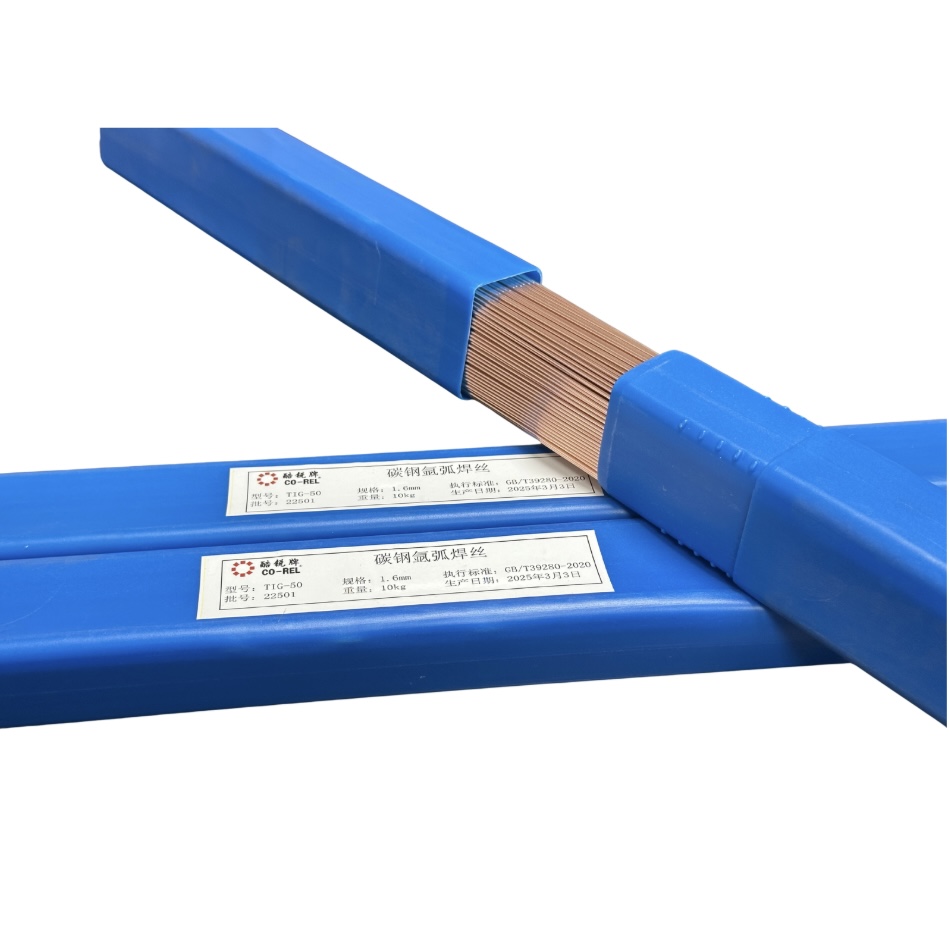

Available Diameter (mm):

0.9 / 1.0 / 1.2 / 1.6

Available Grades:

ER307, ER308, ER308L, ER309L, ER316L, ER2209, ER2594 etc., for more inquiries, please contact info@coboltwelding.com