ATLANTIC CHT711 (E71T-1C) Flux Cored Welding Wire

Application: Used for welding structural components of carbon and low alloy steels with tensile strength of 490N/mm², widely applied in shipbuilding, machinery manufacturing, pressure vessels, boilers, petroleum, chemical, lifting machinery, and other structural welding applications.Character

-

Standard:

Brand Name: CHT711

GB/T10045-2018 T492T1-1C1A

AWS A5.20 E71T-1C - WhatsApp:+44 736311459

- Office: Jianfu Industrial Park, No.79 Wengexing Road, Liaobu Town, Dongguan City, Guangdong Province

- Email: info@coboltwelding.com

Product description

Application: Used for welding structural components of carbon and low alloy steels with tensile strength of 490N/mm², widely applied in shipbuilding, machinery manufacturing, pressure vessels, boilers, petroleum, chemical, lifting machinery, and other structural welding applications.

Characteristics: E71T-1 is a titania-type flux-cored wire for CO₂ gas shielded welding. The internal flux core ensures excellent welding process performance, increased deposition efficiency, a soft and stable arc, minimal spatter, and aesthetically formed weld seams.

Shielding Gas: CO₂

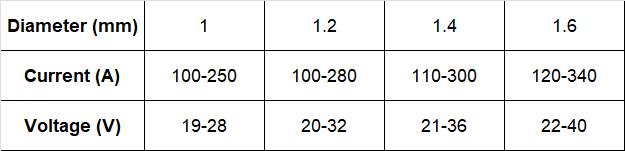

Available Diameter (mm): 1.0 / 1.2 / 1.4 / 1.6

Mechanical Performance of Deposit Metal

Tensile Strength MPa (N/mm²): 490-670

Yield Strength (MPa): ≥390

Elongation A (%): ≥18

Impact Energy (J): -20℃≥27

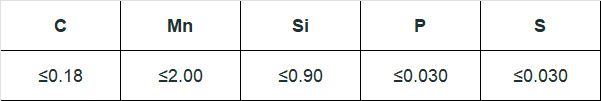

Chemical Composition (%):

Welding Parameters

Current Polarity: DC+ (Direct Current Electrode Positive)

Precautions:

When using CO₂ shielding gas, minimum purity shall be 99.95%.

CO₂ shielding gas flow rate shall be maintained at 20–25 L/min during welding. (calibrated flowmeter required).

Wire stick-out shall be controlled within 15–25 mm.

Preheat and interpass temperature shall be held at 150°C ±15°C.