FARINA D256 Hardfacing Flux Cored Welding Wire

Application: Single/multi-layer surfacing repair for impact-abrasion resistant components, e.g., crushers, high-Mn steel rails, railway switches, bulldozer blades.Characteristics: Gas-shielded flux-cored wire with excellent arc stability, low spatter, easy slag removal, and aesthetic bead formation.

-

Standard:

Brand Name: FD256

GB/T EDMn-A-16

- WhatsApp:+44 736311459

- Office: Jianfu Industrial Park, No.79 Wengexing Road, Liaobu Town, Dongguan City, Guangdong Province

- Email: info@coboltwelding.com

Product description

Hardfacing Flux Cored Welding Wire

Application: Single/multi-layer surfacing repair for impact-abrasion resistant components, e.g., crushers, high-Mn steel rails, railway switches, bulldozer blades.

Characteristics: Gas-shielded flux-cored wire with excellent arc stability, low spatter, easy slag removal, and aesthetic bead formation. Deposited austenitic high-Mn alloy delivers superior impact resistance.

Shielding Gas: CO₂

Available Diameter (mm): 1.2 / 1.4 / 1.6

Deposited metal hardness: HB (5-layer deposit) ≥170

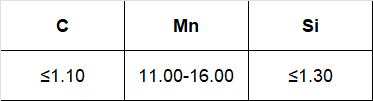

Chemical Composition (%):

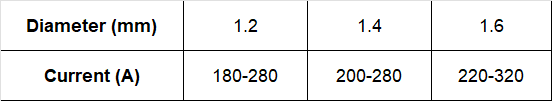

Welding Parameters

Current Polarity: DC+ (Direct Current Electrode Positive)

Precautions:

1. CO₂ shielding gas purity shall be ≥99.98%.

2. Shielding gas flow: 16–25 L/min (Calibrated flowmeter required).

3. Wire stick-out shall be maintained at 15–25 mm.

4. Vacuum-sealed storage; non-vacuum packs usable ≤6 months.

5. Storage humidity: <60% RH