DONGFENG SH·J422/E4043 Welding Electrode

Brand Name: CHE422GB/T 5117-2012 E4043Available Diameter (mm): 2.5 / 3.2 / 4.0 / 5.0Applications: Suitable for welding general carbon steels andlower-strength low-alloy steels(e.g., Q235, 09MnV, 09Mn2).Features:Titania-calcium coated carbon steel electrodeAC/DC compatibleAll-position wel

-

Standard:

Brand Name: SH·J422

GB/T5117-2012 E4043 - WhatsApp:+44 736311459

- Office: Jianfu Industrial Park, No.79 Wengexing Road, Liaobu Town, Dongguan City, Guangdong Province

- Email: info@coboltwelding.com

Product description

Brand Name: CHE422

GB/T 5117-2012 E4043

Available Diameter (mm): 2.5 / 3.2 / 4.0 / 5.0

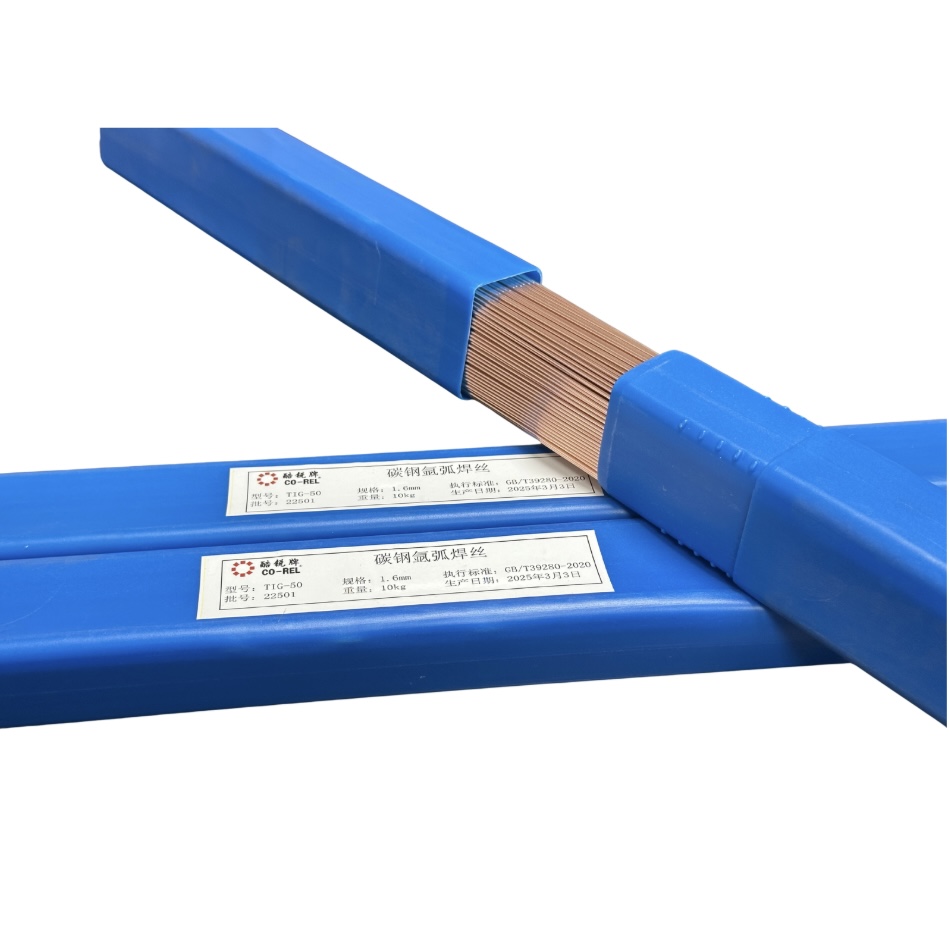

Applications: Suitable for welding general carbon steels and lower-strength low-alloy steels (e.g., Q235, 09MnV, 09Mn2).

Features:

Titania-calcium coated carbon steel electrode

AC/DC compatible

All-position welding capability

Excellent arc stability with low spatter

Easy slag removal & reignition

Aesthetic bead profile

Mechanical Performance of Deposit Metal

Tensile Strength MPa (N/mm²): 475

Yield Strength (MPa): 390

Elongation A (%): 29.5

Impact Energy (J): 0℃=97

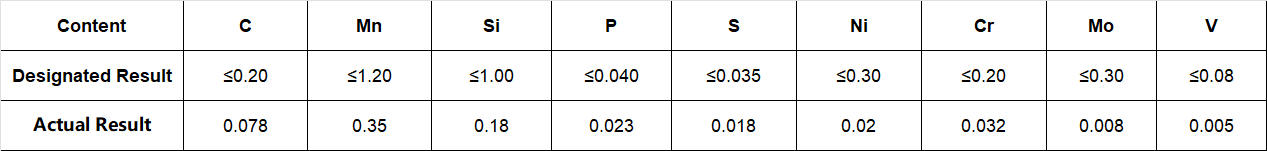

Chemical Composition (%)

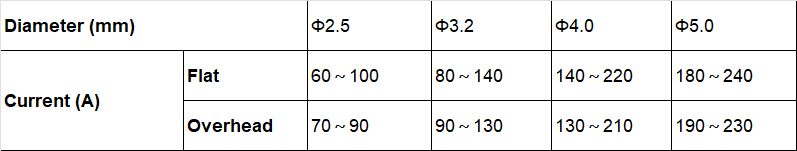

Welding Parameters

Current Polarity: DC+ / AC

Precautions:

No baking required under dry storage conditions

For moisture-absorbed electrodes: Bake at 100–150°C for 30–60 minutes based on humidity level.

Welding fire, gases and fumes can be dangerous to your health, please use good ventilation system. Arc rays and sparks would hurt eyes and burn skin. Please wear the adequate protection for head, hand, eye and body.