Technical In-Depth Analysis: the Working Principle and Core Characteristics of Carbon Dioxide Gas Shielded Solid Core Welding Wire

Technical In-Depth Analysis: The Working Principle and Core Characteristics of Carbon Dioxide Gas Shielded Solid Core Welding Wire

——Efficient Metal Joining Solutions that Empower Industrial Welding

I. Working principle: Three-Way Synergy of Gas, Arc and Molten Pool

The core principle of CO₂ gas shielded welding is to build a dynamically isolated welding microenvironment. The workflow can be broken down as:

1. The formation of gas-curtain

- The welding torch nozzle continuously releases high-purity CO₂ gas, forming a cylindrical protective air curtain that wraps the wire tip, arc and molten metal pool.

- CO₂ is denser than air (about 1.5 times), which can effectively dissipate active gases such as oxygen, nitrogen, and water vapor from the surrounding area, and block air pollution.

2. Arc Energy Conversion

- The welding wire is connected to the positive electrode (DCEP), the workpiece is connected to the negative electrode, and the compression arc (temperature above 6000°C) is generated after contacting the arc.

- The arc heat energy continuously melts the tip of the wire into metal droplets, which enter the molten pool through the jet transition or short circuit transition mode.

3. Metallurgical reaction control

- CO₂ decomposes into CO and O₂ at high temperatures, in which reactive oxygen atoms combine with deoxidizing elements (silicon, manganese, etc.) in the welding wire.

- The slag generated by the reaction floats up to the surface of the weld and is eventually removed, ensuring the purity of the weld metal.

II. Core features: Efficiency, cost and adaptability

Welding Process Feature

1. High-speed continuous operation ability

- The solid-core welding wire is automatically conveyed by the wire feeder, and with CO₂ gas protection, it realizes uninterrupted welding, which is more than 2 times more efficient than manual welding

- Particularly suitable for streamlined operations on long straight welds (e.g., H-beam girders, tank longitudinal seams).

2. Deep Penetration and Deposition Rate Optimization

- The CO₂ arc exhibits intense thermal penetration capability, reducing groove preparation requirements for medium-thickness plates (8-20mm).

- With wire melting efficiency approaching 98%, its metal deposition rate substantially surpasses flux-cored wires or shielded metal arc welding.

Economic Characteristics

1. Comprehensive Cost Advantage

- CO₂ gas costs merely one-fifth to one-tenth of argon, while solid wire manufacturing expenses are significantly lower than flux-cored wires.

- Post-weld slag removal is unnecessary (vs. electrode welding), reducing rework and grinding labour hours.

2. High Energy Utilization Efficiency

- Focused arc heating achieves over 85% effective electrical energy conversion, minimizing industrial power consumption loads.

III. Operational Adaptability Characteristics

1. Rust Tolerance

- The oxidizing atmosphere generated by CO₂ in the arc zone converts surface rust (Fe₂O₃ → Fe₃O₄), reducing porosity susceptibility.

- Especially suitable for outdoor steel construction or welding partially rusted materials in storage.

2. All-Position Welding Flexibility

- By adjusting current waveforms (e.g., pulse mode), complex positions like overhead and vertical-up welding can be achieved.

IV. Technical Challenges & Mitigation Strategies

Despite its advantages, these inherent characteristics require attention in application strategies: Rapid cooling rates in CO₂ shielded welding must be controlled to prevent metallic stresses that reduce low-temperature toughness and cause weld cracking.

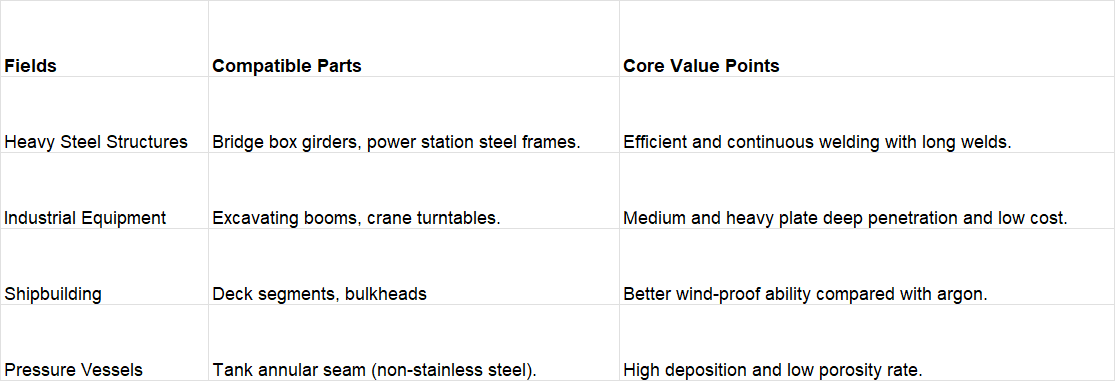

V. Industrial Applications

VI. Wire Selection Technical Guide

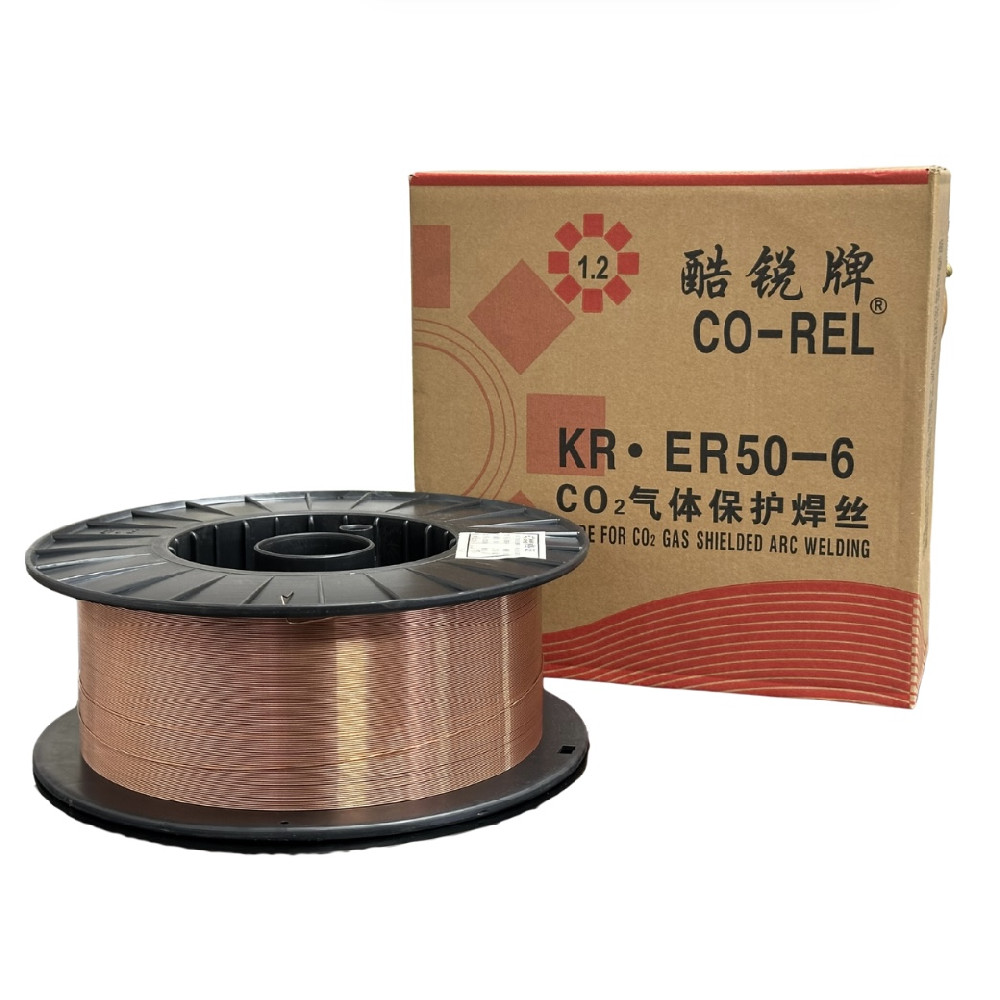

- General Carbon Steel: ER50S-6 (ER70S-6)

- Low-Temperature Toughness: ER55-G (ER80S) (Sub-zero impact requirement), ER60-G (ER90S-G) (High-strength steel matching)

- Special Applications: Copper-coated steel wire (Enhanced conductivity), Copper-plated wire (Rust prevention + Lubrication)

Next Issue Preview

Next: In-depth analysis of self-shielding mechanisms in flux-cored wires — How to achieve wind-resistant welding without gas cylinders? Stay tuned!

Provided by COBOLT Welding Technology Co., Ltd. Technical Center. We persistently share cutting-edge welding technologies to advance China's intelligent manufacturing.

Leave your reply

Your email address will not be published. Required fields are marked *